Precision Pipe Welding with DCT 3D Welding Table and Modular Fixtures

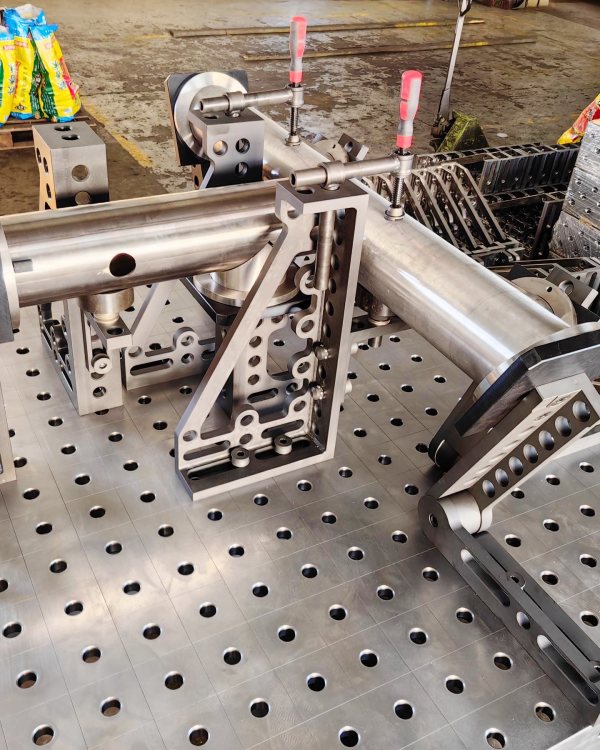

DCT 3D welding tables offer exceptional precision, stability, and flexibility for demanding pipe welding applications. Engineered with nitrided or chrome-plated surface treatments, these tables provide high wear resistance, corrosion protection, and extended service life, even under heavy use.

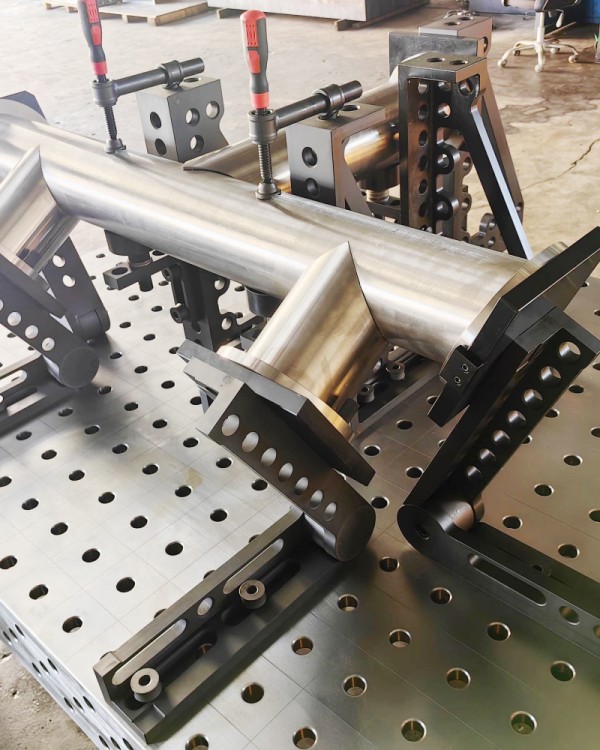

The modular fixture system is a key advantage, allowing fabricators to accurately position and secure pipes, elbows, and T-joints at complex angles. With CNC-machined grid holes and universal slot compatibility, setup becomes faster and more efficient, minimizing the need for custom jigs or manual adjustments.

DCT accessories—including V-blocks, angle brackets, support arms, and quick-action clamps—enhance productivity by offering reliable holding force and repeatable setups. Each accessory is made from hardened steel, ensuring durability and alignment accuracy during high-temperature welding operations.

The system is ideal for industries that require structural integrity and geometric precision, such as pipeline construction, HVAC, automotive, shipbuilding, and heavy equipment manufacturing. It supports welding processes like MIG, TIG, and flux-cored welding, adapting to both small and large pipe diameters.

Another standout benefit is reduced setup time and improved workflow consistency, helping fabricators achieve higher quality welds with less rework. The ergonomic design of the fixtures also ensures safe, comfortable handling during long hours of operation.

Globally available and easy to integrate into existing workshops, DCT welding tables are a smart investment for boosting efficiency, repeatability, and precision in any pipe welding project.

Please feel free to contact us if you are interested:

Email: info@enjoy-sound.com

susan-chen@enjoy-sound.com

WhatsApp: +86-180-2874-2690